EXTRUDEX Pilot and Demonstration Machines

Scroll down to have a look at demonstration machines from our pilot facility which are currently for sale. If you would like to have further information on these machines, please do not hesitate to contact us. All machines shown are subject to prior sale.

All EXTRUDEX machines and equipment carry CE marking certifying full compliance with corresponding EU standards.

bella EXTRUDEX single screw extruder EN 050-25D Horizontal execution

bella EXTRUDEX single screw extruder EN 025-25D Horizontal execution

bella EXTRUDEX single screw extruder EN 020-25D Horizontal execution

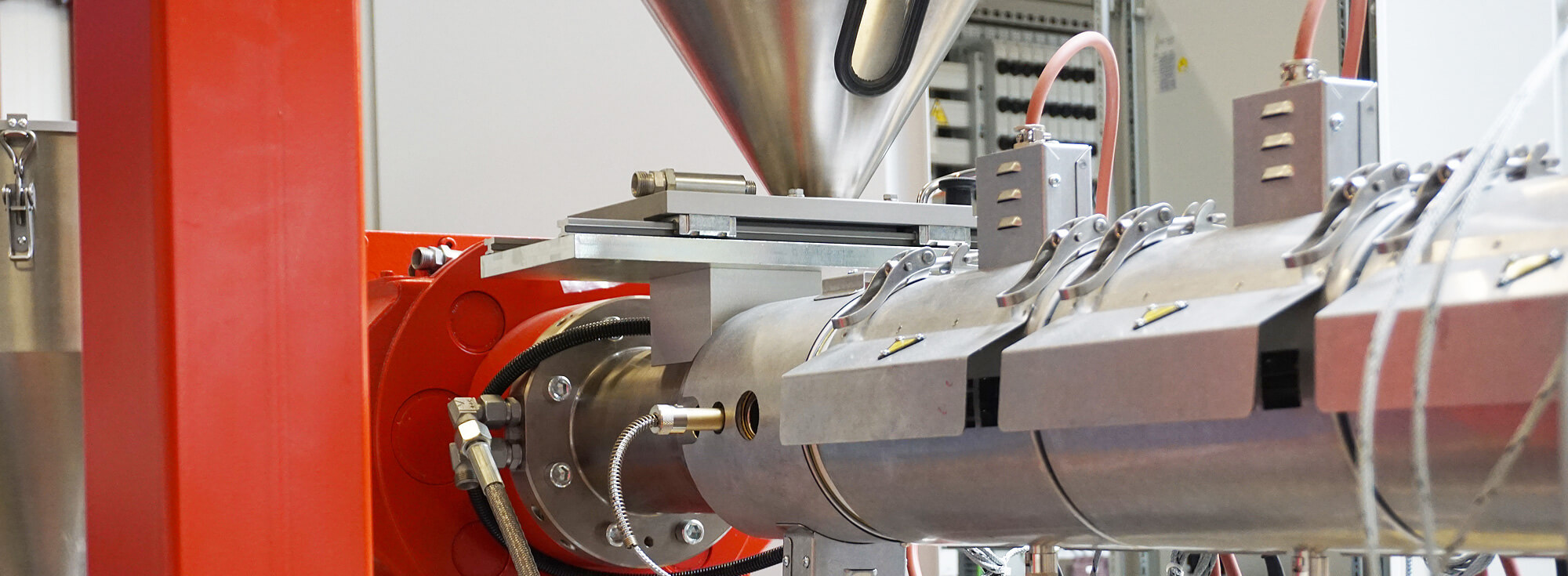

Single-Screw-Extruder HELIBAR® HB 080-30D

- Extrusion height: 1050 mm, +/- 50 mm

- Operating side: Left , seen in extrusion direction

- Material: PE, PP,and other polyolefines (please send us the material specifications before you order)

- Throughput: max. 420 - 480 kg/h

- Screw rotationspeed: max. 105 U/min

- Screw torque: 11370 Nm (theor.)

- Drive: AC-motor, 125 kW frequency-controlled

- Control cabinet: mounted on the base frame of the extruder, incl.

- Scope of supply control: Sigmatek EC 400 for extrusion lines with

- Control different applications

- Operation over ETV control panel, 12" TFT-Touch-display

- The machine comes from our technical department

- Price on request

Two-Chamber Calibration bath type VB 600 for the calibration and cooling of pipes and tubes

Dimension

- tank cross section (WxH): 250 x 200 mm

- vacuum-chamber 1: 950 mm

- vacuum-chamber 2: 4.350 mm

- full-bath/: 400 mm

- drying chamber: 300 mm

- Operating side: right, from the view of the screw feeding direction

- Extrusion height: 1.050 mm +- 50 mm

- Paint RAL 5015, skyblue

Spefifications

- bath made of stainless steel, round edges for better cleaning

- all parts which are in touch with water are made of stainless steel

- Operation over control panel, 6" TFT-Touch-Colour Display

- water temperature indication in all chambers over digital indication

- frame made of stabil steel-pipe design, with 6 height adjustable feet, uncovered

- profil-guiding with 14 single adjustable prism-rolls

Adjustment

- Manual precision cross-adjustment ± 25 mm

- Manual, smooth running longitudinal adjustment over toothed rack ± 200 mm

- Hand-wheel ergonomically mounted on the operating side

Vacuumsystem

- Vacuum generation by frequency-controlled pump

- 1 vacuum fine-regulating valve (in chamber 2)

- 1 quick-ventilation with noise-absorber

Calibration

- Water supply over 4-fold continuous flow controller

- Water column for constant water-pressure at the calibration inlet

- including EVS (Electronic Vacuum System) for higher process stability

- There are 2 regulation modes available:

- 1. Active maintaining of the vacuum level

The vacuum will be adjusted to the chosen level, also if e.g. wear of the vacuum sealing occurs due to long-time operation. - 2. Automatic regulation of the vacuum depending of outer diameter

Adjustment of the vacuum level in the operating chamber as it gets below the minimum / over the maximum tolerance level, dependent on the extrusion line speed. (only in combination with optional diameter measuring system)

Price on request

Extruder EM012-25D

- Technical data of Machine

- extrusion height: 1000 mm

- operating control display integrated in console

- throughput: 0.5 – 1.0 kg/h, depending on raw material processed and tooling dimensions

- drive: 1.3 kW servomotor

- screw speed: max. 100 rpm, screw exchange from front

- torque: 95 Nm