High-Speed Extrusion Lines

For Medical Tubing Manufacturing

EXTRUDEX offers a broad spectrum of complete single-source solutions (turn-key solutions) for:

- manufacturing of multi-lumen medical tubing

- manufacturing PP and PE medical tubing in O.D. range 2 – 4 mm

- manufacturing of flexible PVC medical tubing in O.D. range 2 – 12 mm

- manufacturing of 3 to 6-layer medical tubing

Well-known manufacturers in the medical and laboratory equipment sectors worldwide rely on quality solutions from EXTRUDEX.

All EXTRUDEX extrusion lines carry CE marking certifying full compliance with corresponding EU standards.

Coextrusion line for 3 to 6-layer tubing with an overall wall thickness of 0.275 mm

- for catheter tubing manufacturing

- provides co-extruded layers consisting of up to 6 different resins

- resins: LDPE – PEBAX – TPU – EVA – CAPA – CAPA

- overall wall thickness: 0.275 mm

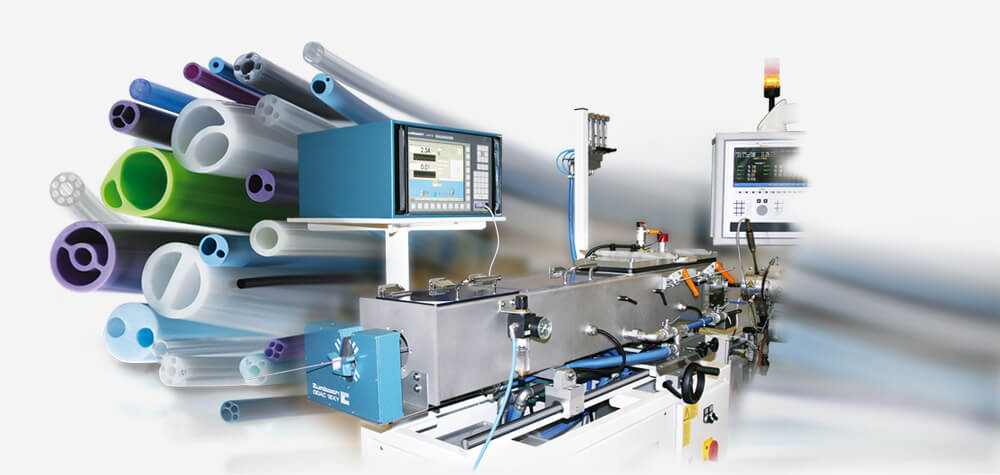

Extrusion line for manufacturing of multi-lumen medical tubing

- Resins: TPU, PUR, PA, PEBAX

- O.D. range: 0.8 mm – 8 mm

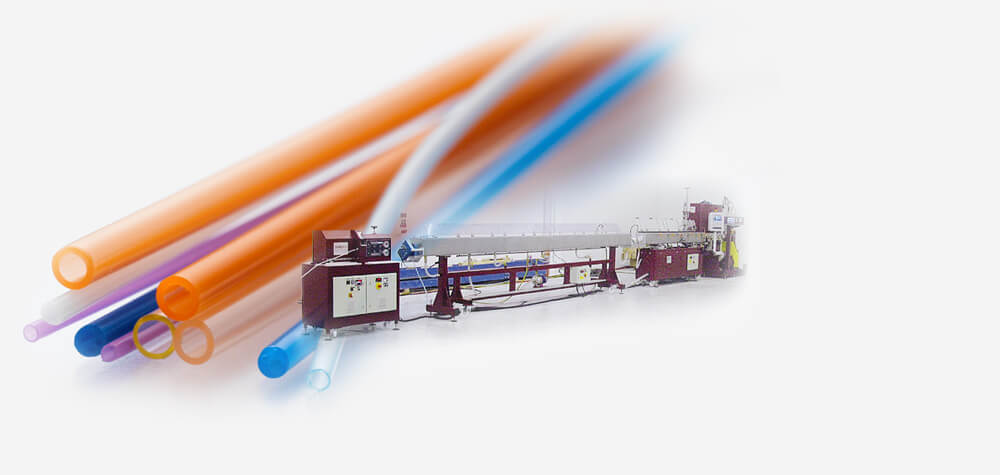

High speed extrusion line

- for manufacturing of flexible PVC medical tubing

- in O.D. range 2 – 12 mm

High-speed extrusion line

- for manufacturing PP and PE medical tubing

- O.D. range 2 – 4 mm

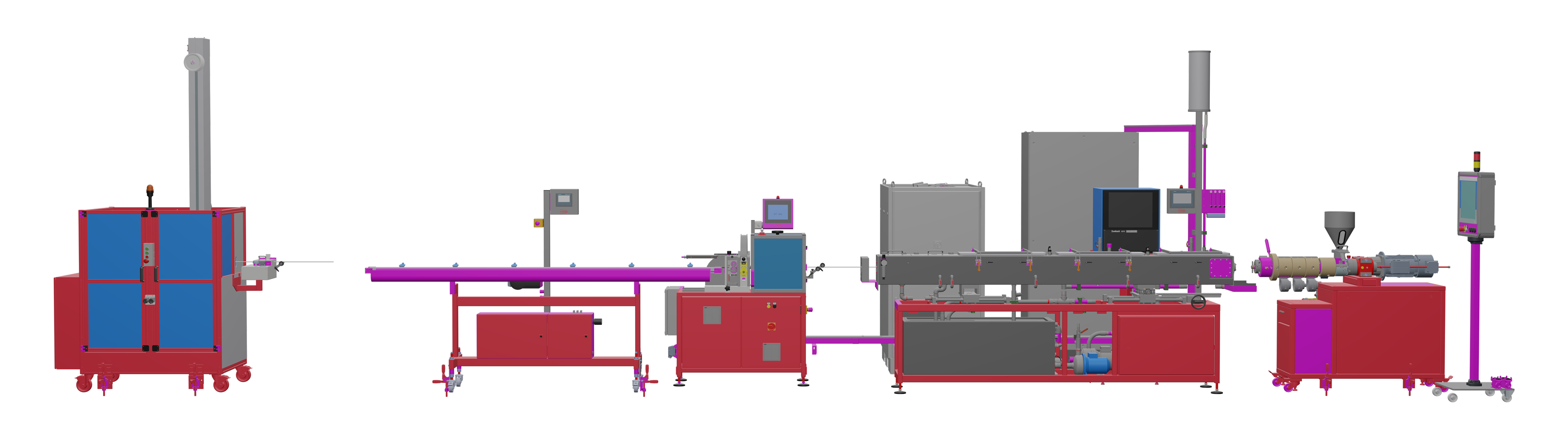

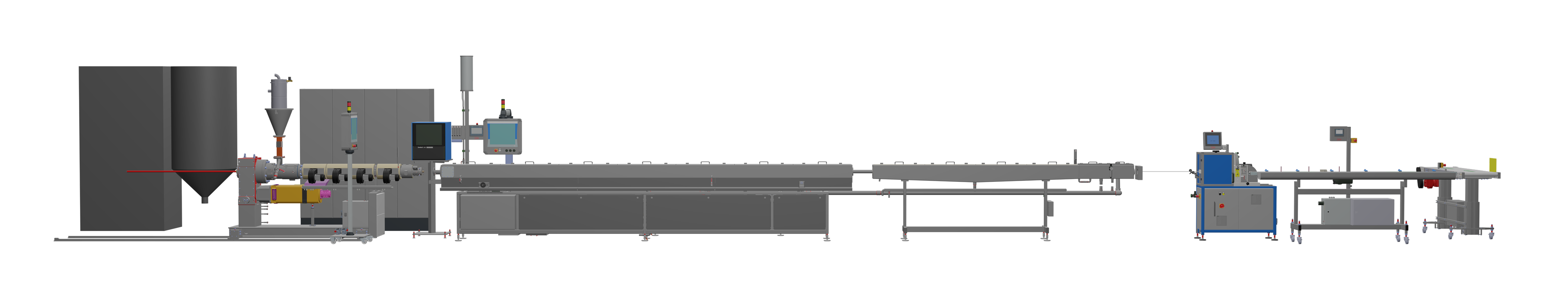

Extrusionline designed for the production of medical tubings

in stainless steel execution for the extrusion of medical mono- and multi-lumen tubes made of thermoplastic materials like TPU, PA und PEBAX for cleanroom class 8 according to ISO 14644: 1999 (equivalent to class 100.000)

Consisting of

1x Drying-and conveying-system with platform

2x De-Dusting unit Pelletron

2x Single screw extruder EN 020-25D

1x Support-air module

2x Crosshead RW5Q with adapter for stripes

1x Vacuum calibration bath VB 300 with EVS

1x Set of disc-calibration

1x Set of block-calibration

1x Measuring – and drying chamber

1x Wallthickness and diameter measuring system Wallmaster

1x Set of blow-off nozzles

1x Automatic inspection system Tymor 3100 with 6 cameras

1x Belt haul-off / cutter combination BC 034

1x Conveying- and blow-off unit AT 300

1x Chiller for cooling of the cooling water

1x Plant control Siemens S7-1500/19" or Sigmatec EC 400/19“

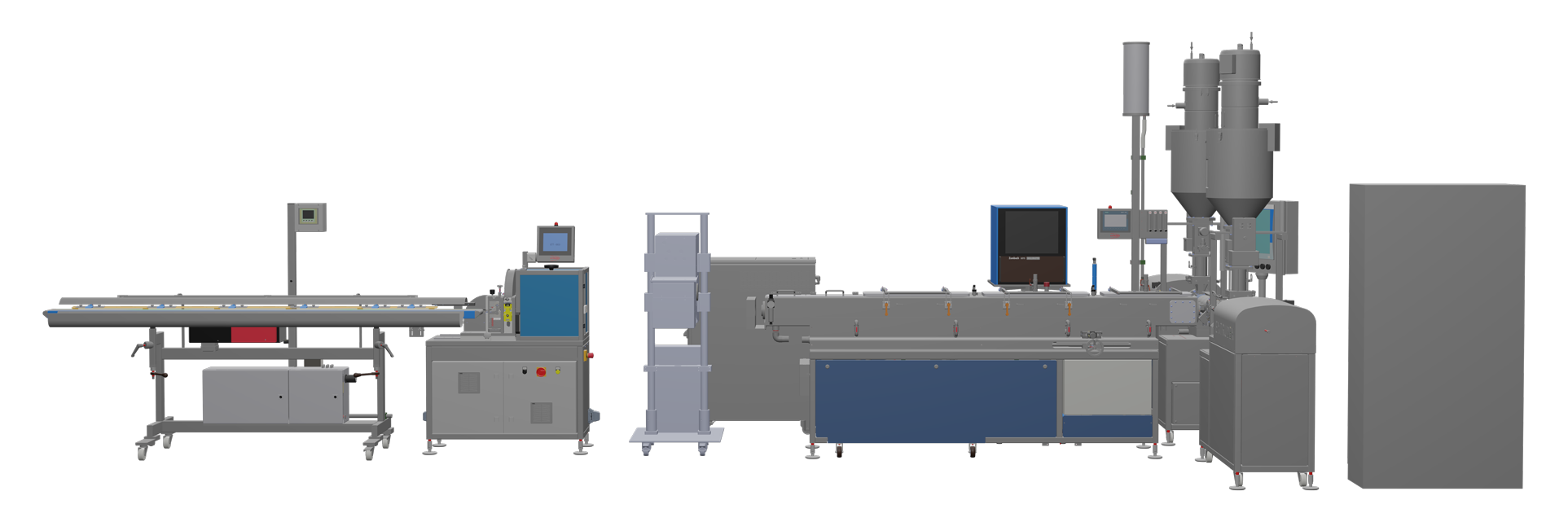

Extrusionline designed for the production of medical hoses

This EXTRUDEX extrusionline is designed for the the production of urinial catheters made of TPU.

This line fullfills cleanroom class 8 specifications according to ISO 14644: 1999 (equivalent to class 100.000)

Consisting of

1x Material conveyor for a capacity of approx. 100 kg/h

Drying system for 400 liter hooper incl. timer

Extraction system for hopper draining

1x Single screw extruder EN 060 – 30 D, movable on rails

1x Heat-exchanger for EN 060

1x Adapter with heating

1x Tube die-head RW 020

1x Pre-cooling chamber incl. flange

1x Set disc-calibration

1x Vacuum calibration bath VB 300 with EVS

with electronical positioning

with electrical height adjustment

2x Water-cooling bath WB 600

1x Measuring – and drying chamber

1x Wallthickness and diameter measuring system Wallmaster

1x Blow-off-nozzles

1x Extrucut BC 034 with air cooling of knife

1x Transport and blow off device AT 300

1x Lenght measurement system – up to 472 mm

1x Cross conveyor belt

1x Chiller

1x Plant control Siemens S7-1500/19" or Sigmatec EC 400/19“

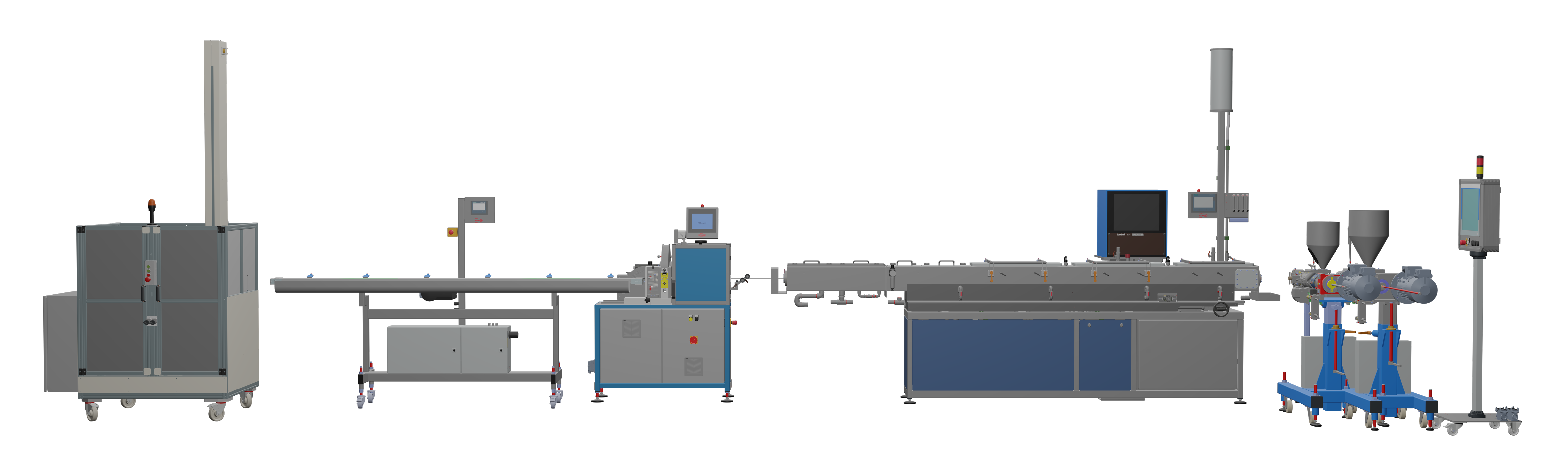

Extrusionline designed for the extrusion of medical mono- and multi-lumen tubes

for cleanroom class 8 according

to ISO 14644: 1999 (equivalent to class 100.000)

Consisting of

2x Single screw extruder EN 020-25D

1x Support-air module

2x Crosshead RW5Q with adapter for stripes

1x Vacuum calibration bath VB 300 with EVS

1x Set of disc-calibration

1x Set of block-calibration

1x Measuring – and drying chamber

1x Wallthickness and diameter measuring system Wallmaster

1x Set of blow-off nozzles

1x Belt haul-off / cutter combination BC 034

1x Conveying- and blow-off unit AT 300

1x Winder for medical tubing - ED - SW025

1x Plant control Siemens S7-1500/19" or Sigmatec EC 400/19“

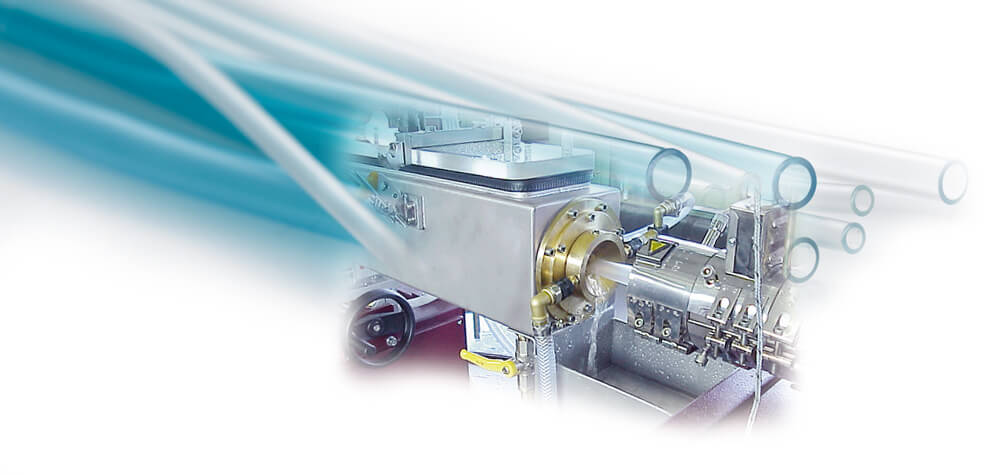

Fluoropolymer extrusion line for producing 1 – 3 lumen tubes

Material: FEP

Product dimensions: for mono and multi-lumen tubes: max. 4 mm O.D.

Consisting of

1x single screw extruder EN 020 -25 D - fluor

1x cross spray head RW05Q – Hastelloy

1x tool insert - Hastelloy

1x adapter - Hastelloy

1x 4-fold support air module

1x vacuum calibration bath VB 300 with EVS,

including water temperature control and insulation of water tank

1x measuring and drying chamber

1x diameter measuring system Wallmaster ODAC 13 XY

1x cooling device approx. 20.8 KW, type Riedel

1x haul-off cutting unit BC 034

1x tilting table AT 300

1x double rewinder for plastic hoses, with dancer control

1x line control Siemens S7-1500/19" or Sigmatec EC 400/19"