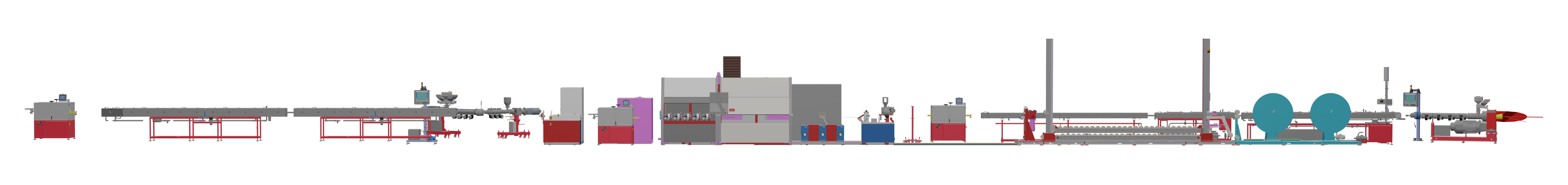

Sanitary tubes

Extrusionline designed for the production of sanitary hoses

made of PE-RT designed for tubes with outer diameter 14,0 mm – 32,0 mm

Consisting of

1x Gravimetric dosification unit SAVEOMAT

1x HELIBAR® HB 070 – 30 D extruder for inner-layer

4x Co-extruder EN 025-25D

1x Set ball-head adapter

1x 5-layer co extrusion die-head Vario-San RW 532

1x Set disc-calibration

1x Vacuum calibration bath VB 600 with EVS

1x Vacuum calibration bath VB 600 ecoline

2x Spray-cooling bath SB 600

1x Measuring – and drying chamber

1x Wallthickness and diameter measuring system Wallmaster

1x Blow-off-nozzles

1x Haul-off BA100

1x Plant control Siemens S7-1500/19" or Sigmatec EC 400/19“

1x Coiler on request

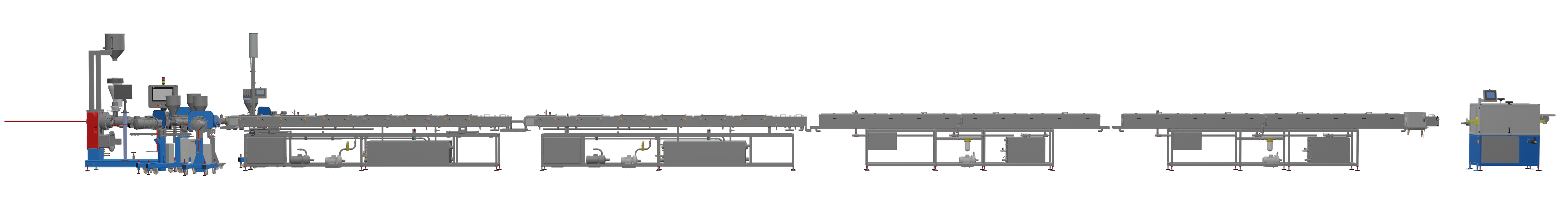

Extrusionline designed for the production of aluminium composite tubes

Compositionn of tube: PE-RT-Admer-Alu-Admer-PE-RT

Dimensions: 16 MLP – 32 MLP, für 16 – 20 – 25 – 32 - 40

Aluminium: AIMn1Cu; 3.0517, Thickness 0,2 – 0,5 mm

| OD: | Line-speed: |

| (mm) | (m/min) |

| 16 | 40 - 50 |

| 20 | 35 - 45 |

| 25 | 22 |

| 32 | 20 |

| 40 | 18 - 20 |

Consisting of

EXTRUSION INNER-LINER AND ADMER

1x Material conveying system Koch 1320D

1x HELIBAR® HB 070 – 30 D extruder

for inner-layer

1x Crosshead RW 040 with carriage

1x Crosshead RW 063 with carriage

1x Vacuum-calibration bath VB 600

1x Vacuum-calibration bath VB 300

1x Water bath WB600

1x Haul-off BA100

1x Dancer

1x Extruder EN 030-25D

1x Cross-head for adhesive coating - RW030Q

1x Haul-off BA100

1x Wallthickness and diameter measuring system

1x Dancer

Metal sheating system for the

production of multi-layered

composite pipes

1x Double-Uncoiler

1x Double-Uncoiler

1x Strip deflection

1x Cross welding machine RSM 120

1x Strip accumulator (looping tower)

STRIP PREPARATION

1x Straightening station

1x Slitting station

1x Double edge scrap winder

FORMING AND WELDING - TIG welding

1x Welding machine ACDC – PWU 400 ACDC

CALIBRATION AND HEATING

1x Transistorized medium frequency converter ITPA 10 K 60

1x Inductor coils ITIN 20 H 100

WELD SEAM TESTING

1x Eddy current testing system E-5 compact

EXTRUSION ADMER AND OUTER LAYER

1x Haul-off BA100

1x Extruder EN 030-25D

1x HELIBAR® HB 040 – 30 D extruder

1x 2-layer coating head RW 250-Q

1x Spray cooling bath SB 600 standard

1x Measuring – and drying chamber

with

1x Diameter gauge ODAC 63 XY

1x blow-off-nozzles

1x Haul-off BA100

1x Plant control Siemens S7-1500/19" or Sigmatec EC 400/19“