Extrusion Lines for Automotive Products

EXTRUDEX lines manufacture automotive products with consistently high quality, providing outstanding operating efficiency and rock-solid process control.

- Reduced energy consumption due to quick ramp-up from start-up to production mode.

- Product-specific process parameters and ramp are stored in process recipes which can be recalled and implemented at the push of a button. When the production line speed is attained, in-line O.D. and wall thickness monitoring begins and any out-of-spec products are separated off. The result: start-up scrap and resultant costs are held to a minimum.

- Process and product data are gathered, externally stored (optional feature) and displayed in process control charts.

All EXTRUDEX extrusion lines carry CE marking certifying full compliance with corresponding EU standards.

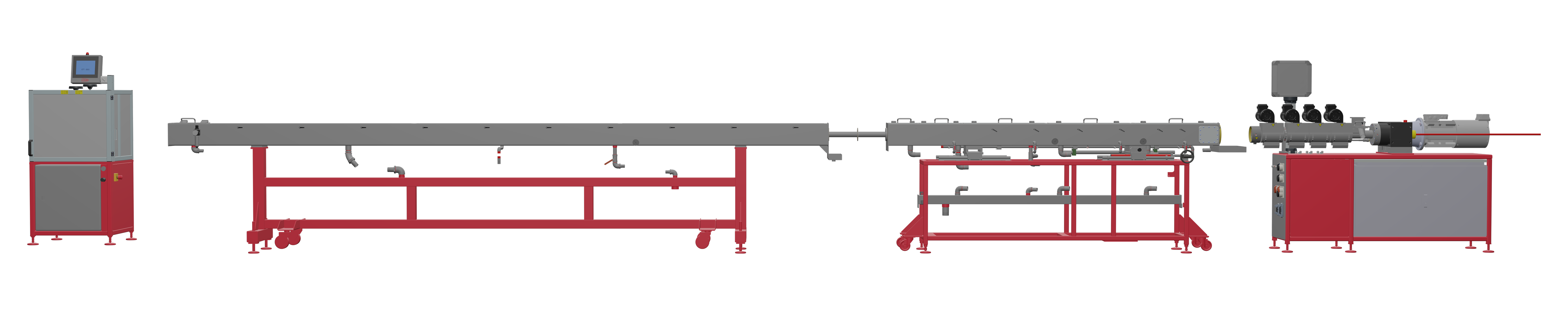

Extrusion Line

- for manufacturing of mono- and 3-layer automotive pipe

EXTRUDEX monolayer-tubing line for tubes made of PA 12 / PA 11 / PA 6.12 / PA 6 with an O.D. of 4,0 - 25,0 mm and WT 0,5 - 3,0 mm

Consisting of

1x Single screw extruder EN 060 – 25 D

1x Tube die-head RW 020

1x Tube die-head RW 040, with carriage

1x Set disc-calibration

1x Vacuum calibration bath VB 600 with EVS

1x Water-cooling bath WB 600

1x Measuring – and drying chamber

1x Wallthickness and diameter measuring system Wallmaster

1x Blow-off-nozzles

1x Extrucut BC 105P

1x Plant control Siemens S7-1500/19" or Sigmatec EC 400/19“

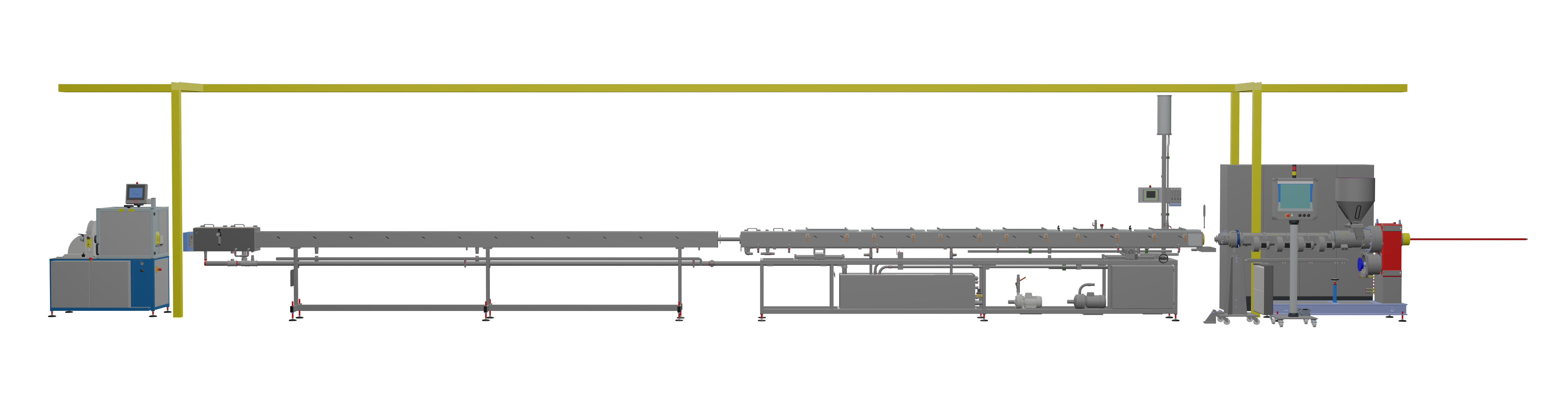

EXTRUDEX monolayer-tubing line for tubes made of TPE and TPU

Consisting of

1x Single screw extruder EN 060 – 25 D

1x Metal-separator

1x Screen-changer BDL 60/60

1x Melt-pump Maag

1x Adapter with heating

1x Tube die-head RW 040, with carriage

1x Set disc-calibration

1x Vacuum calibration bath VB 600 with EVS

2x Water-cooling bath WB 600

1x Measuring – and drying chamber

1x Wallthickness and diameter measuring system Wallmaster

1x low-off-nozzles

1x Extrucut BC 105P

1x Conveying- and blow-off unit AT 600, including online lenght measuring system

1x Serial winder, DW 800 RT/2

1x Chiller

1x Plant control Siemens S7-1500/19" or Sigmatec EC 400/19“

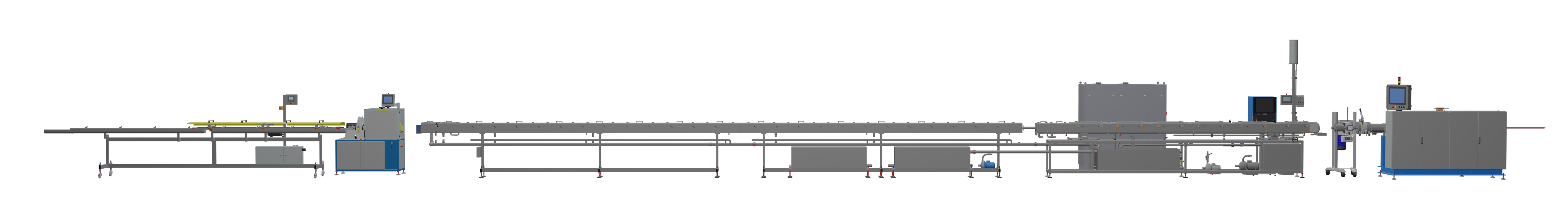

Extrusion line for producing piping profiles

Consisting of

1x extruder HELIBAR® HB 030 – 30 D

1x profile tool with heated adapter

1x tool insert

1x vacuum calibration bath VB 300 with EVS

1x water bath WB 600 with drying chamber

1x haul off BA 050

1x line control Siemens S7-1500/19" or Sigmatec EC 400/19"