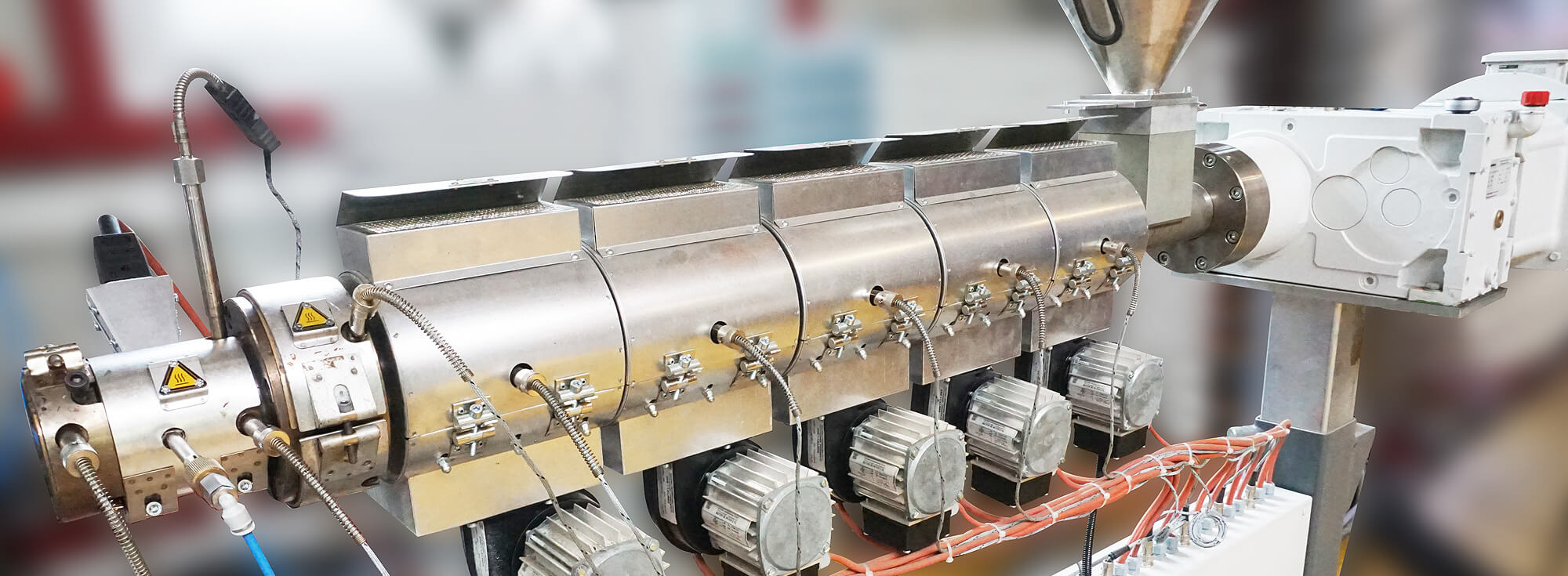

EXTRUDEX Grooved-Barrel Extruders

EXTRUDEX extruders with grooved intake zones provide significant benefits including:

- High pressure build-up and high pressure stability

- High specific throughput rates

- High intake and output consistency

These benefits are realized with all thermoplastic resins which are suited for solid-phase transport within grooves, i.e. which exhibit low "outer friction". Process-relevant components such as the screw and the grooved barrel are designed and/or optimized in accordance with the intended application at hand.

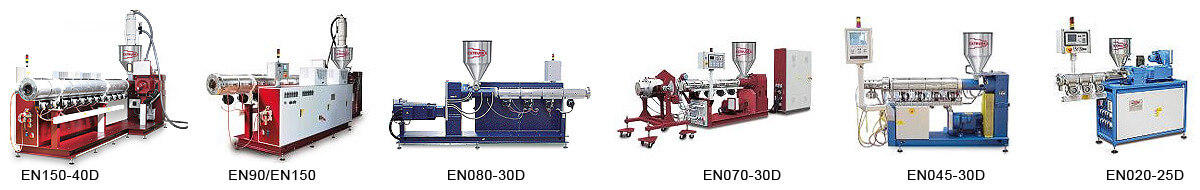

EXTRUDEX Grooved-Barrel Extruders Standard Designs

EXTRUDEX grooved-barrel extruders are available in standard versions with screw diameters from 20 to 150 mm and screw lengths of 25 L/D and 30 L/D.

All EXTRUDEX extruders carry CE marking certifying full compliance with corresponding EU standards.

| TYPE | Screw-Ø | Screw length L/D |

|---|---|---|

| EN020 | 20 mm | 25 30 |

| EN025 | 25 mm | 25 30 |

| EN030 | 30 mm | 25 30 |

| EN035 | 35 mm | 25 30 |

| EN040 | 40 mm | 25 30 |

| EN045 | 45 mm | 25 30 |

| EN050 | 50 mm | 25 30 |

| EN060 | 60 mm | 25 30 |

| EN070 | 70 mm | 25 30 |

| EN075 | 75 mm | 25 30 |

| EN080 | 80 mm | 25 30 |

| EN090 | 90 mm | 25 30 |

| EN100 | 100 mm | 25 30 |

| EN110 | 110 mm | 25 30 |

| EN120 | 120 mm | 25 30 |

| EN130 | 130 mm | 25 30 |

| EN140 | 140 mm | 25 30 |

| EN150 | 150 mm | 25 30 |

Grooved-Barrel Extruder Solutions

Custom-designed solutions of various types can be realized in exact accordance with the customer, product and quality requirements at hand.